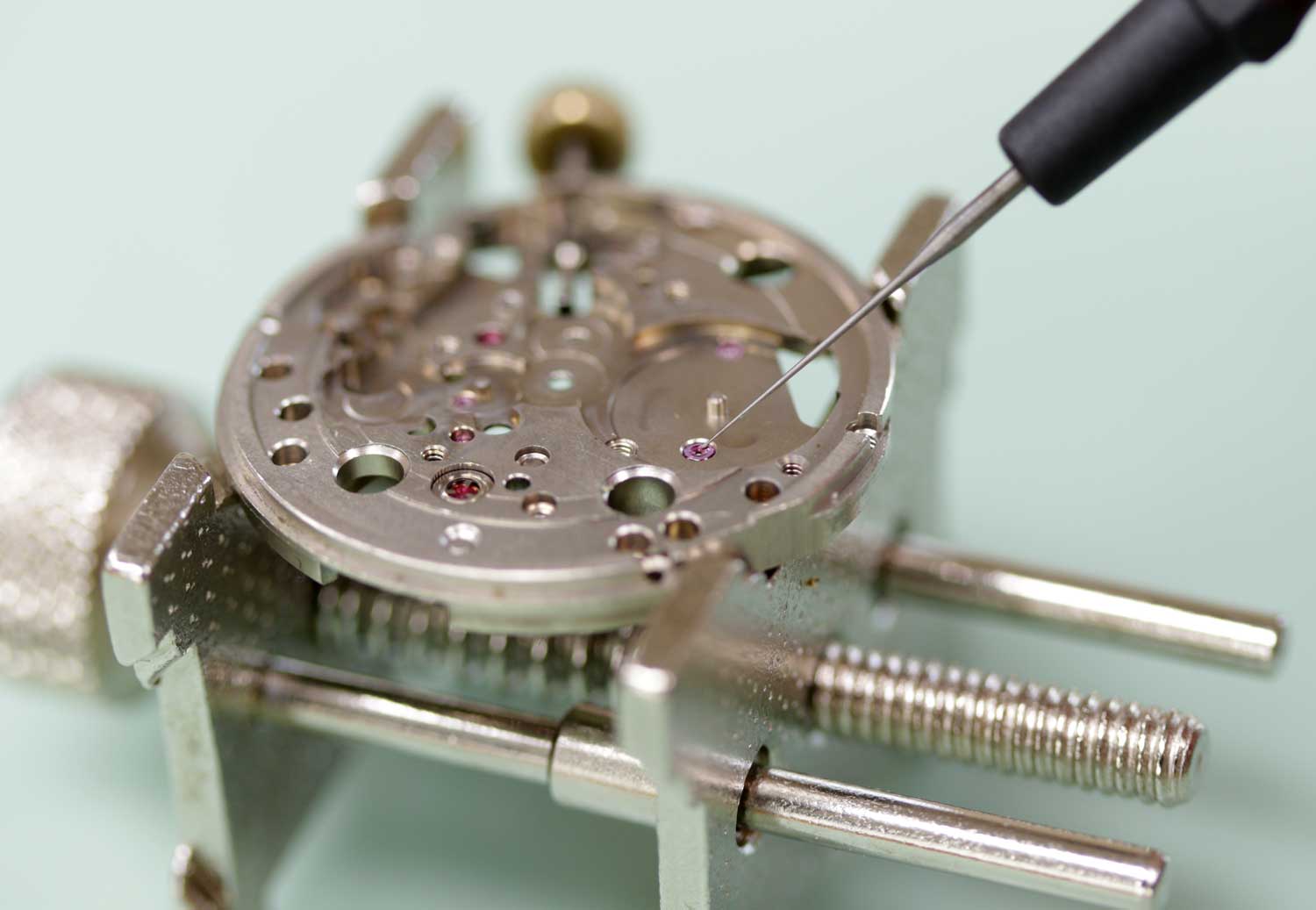

The design of a mechanical watch movement requires regular maintenance including lubrication to reduce the friction on moving parts that causes them to wear out. There are over 50 areas of friction that need to be oiled in a typical wrist watch and the more complications on the watch, the more areas that need to be oiled. Just as any mechanical engine needs an oil change, the automatic and manual mechanical watch needs lubrication or sometimes a cleaning and complete oil change; or as watchmakers say “Overhaul”.

This article will help watch enthusiasts and hobbyists learn the basics of oiling mechanical wrist and pocket watches and cover the most common and important areas that need oil along with choosing the correct oil for different components.

You can usually tell if your watch needs to be oiled if it starts to run slow and loses accuracy. When the oil dries up it leaves the parts rubbing together and eventually the friction will cause the metal to sheer and dirt to build up. If you open the watch you can visually see that the jewels might be dry or crusty with old oil and dirt or even see some wear and tear on the metal plates and gears.

Oiling is typically done at scheduled service intervals, but if you just bought a new-to-you vintage watch it more than likely needs to be oiled as the oil has probably dried or gummed up. If you are unsure of when the last service was completed on the watch it is best to have the watch overhauled. This means the watch needs to be completely dis-assembled, cleaned, and re-oiled to the manufacturer specifications for optimal performance.

If you are just looking to quickly get your watch running again

you can get by with a simple oiling of the jewels and escapement – but don’t expect it to run like new. You can get by with a minimal oiling job if all you really want is the watch to keep time – you may not need or care if the additional features stop working, such as the day/date, timer, and other chronograph features (and they might not without a proper cleaning and oiling service). You may not like the idea of dis-assembling your watch to completely clean and re-oil but it is well worth the effort. Most of the parts are not necessarily hard to get to, but some dis-assembly is required to get to parts that need to be oiled that are not accessible from the surface of the watch movement.

For optimal performance and accuracy, manufacturers recommend that the movement be dis-assembled, cleaned, dried, and then assembled and oiled to specification. Oiling an already dirty watch will trap dirt and debris and cause the oil to spread around the movement and make the watch run poorly.

Today, most watches are oiled with a synthetic oil because it won’t gum up like natural oils will. When synthetic oil is past its lifespan it will simply evaporate. It is always recommended to oil to the specific watch manufacturer specifications but here is a list of generally what oil is used for mechanical watch movements.

Moebius 9010 – The most popular oil because it is a light, synthetic oil that is used for high speed low pressure areas, cap jewels, train gear, pivots, pallet jewels, balance staff, and regulating parts.

HP 1300 – HP1300 (also known as Moebius 9104) is a thicker synthetic oil commonly used for barrel arbors, oscillating weight, center wheel, and third wheel. Sometimes used on setting systems and calendars.

Moebius 0941 – A fine oil used for pallet jewels and the escapement.

Click here for more detail of when to use Moebius oils

Moebius 8200 – A natural grease that is used to lubricate the mainspring

When oiling a watch it is important to not over or under oil and this can create more problems in the near future. You can often find the technical documents for your watch movement that will tell you where to oil and with what kind of lubricant to use and sometimes how much oil to use. Use your best judgement, not so much that its running off the part but enough that it covers the surface. If you place too much it can bleed over into other areas where you don’t want it and that can cause problems.

One thing you can use to help keep the oil where you want it is Epilame. It is commonly used on areas running at high speed like the escape wheel and pallet for jewels and sometimes on the balance cap jewels.

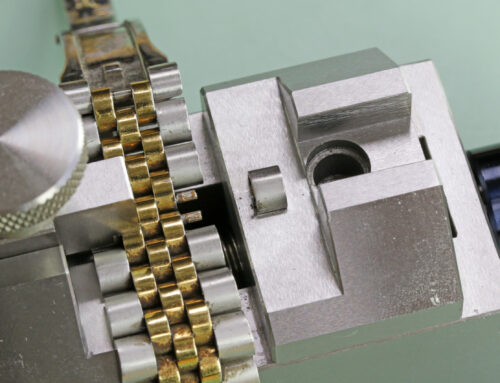

There are some chief supplies you need for basic oiling: some kind of oil applicator, an oil cup or well and the oil itself.

Dip oilers are the most common applicator for oil; simple to use and inexpensive. They come in a variety of sizes that are color coded for quick identification. You simply dip the tip of the oiler into the oil to pick up a drop and then place it onto the area to be oiled. Capillary action then pulls the oil onto the watch part. The tips of dip oilers can even be shaped to your preference with sandpaper.

Automatic oilers are for more precise oiling and often recommended for Rolex watches. These oilers are fully automatic with a press of a button so you can place a minute particle of oil just where you want it.

Oil cups are just what they sound like: a reservoir for the oil. You don’t want to use oil straight from the jar of oil as that will contaminate your whole supply of oil so you should use oil cups with lids to use only a small amount of oil and keep it clean. Keep the lid closed when not in use so that dust and dirt doesn’t get into it and always dip the oiler nib into the side of the cup instead of the middle for the same reason. If there are contaminants in the oil they will gravitate to the middle of the oil cup.

- Be careful not to press too hard into the oil cup when picking up oil so that you don’t break the tip of the oiler. Ruby oil cups are better than plastic to reduce friction when picking up oil.

- Make sure to clean the oiler tips between uses with Rodico or some spongy/foam material. Replace the oil in the cups with fresh oil after about a week and clean the cups between uses. Pay attention to the expiration date on the oils, as it can lose its effectiveness over time and may not last in the watch to the next service date.

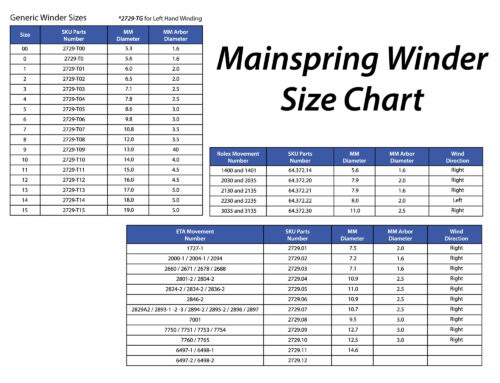

Technical documents are a great resource for watchmakers and hobbyists alike.

They give you all the information you need on a given movement and one of those is what parts to oil with what kinds of oil. Some will even tell you how much to use as well. Here is an example of one for the ETA 2826-2 movement; here you can see the three main oils used and how they are labeled on the diagram that shows all the parts of the movement.

You can find our compiled lists of technical documents from several different watch brands here

Here are the parts of a watch that need to be oiled and where to oil them.

Any place that you see a jewel should be oiled because it is a point of friction where a wheel or gear pivot runs through it.

The critical components that generally require oil and can help get your timepiece running again are the escape wheel, balance staff, and the pallet fork.

The Balance Staff needs to be oiled at the bottom and top jewels with a light oil such as Moebius 9010

Not all surfaces should be oiled and doing so could cause major problems

Its critical that you don’t get oil on the gears, or hairspring, if so it must be removed and cleaned or replaced.

Escape wheel needs oil at the bottom and top jewels with Moebius 0941

Pallet Fork needs oil at the bottom and top jewels with Moebius 0941

Mainspring if it needs to be re-oiled use one-dip to clean then re-grease with Moebius 8200 by using a cloth to apply the grease to the length of the mainspring

Oscillating Weight oil the jewels with the heavier Moebius HP1300

Clutch and Stem The clutch should be oiled at the end and then along the flat side of the stem that runs through the clutch

Gear Train – Oil the individual gears such as: hour wheel inside shaft, minute wheel outside shaft, and more on the ends at the jewels with Moebius HP1300 or 9010

This is a very helpful Website I learned a lot about watches

This website is a terrific find…good job!

I TOO LEARNED A LOT ABOUT MY WATCH.. THANK YOU. RB IN HENDERSON NV

A suggestion is to take photos of your movement every time when you dissemble each part so you know hold to put it back together. Great tips and information

Hello.

Which. oil is best to ball bearing that in automatic module ?

Also for mainspring of the rolex watches ?

best

celal

I’m a novice.

My common sense tells me, if you don’t know the answer to your question, don’t work on Rolex watches.

Hi I’m from Ireland and new to watch Collecting ,Im Really Enjoying Reading and looking at the Diagrams of watch Parts ,,Thanks you Have Been A Great Help explaining oils and Part names ,,

Regards Niall,,

I have a pocket watch that belonged to the Sheriff of Londonderry, Henry Stacy Skipton from the 1830’s. It has the Skipton coat of arms and also the Kennedy coat of arms on the back of it and his initials on the front. I will be in Dublin and Northern Ireland in April 2022 and am bringing the watch with me. It currently does not work though I am thinking about a complete takedown, ultrasonic bath, and possibly remaking and installing some of the more worn gears to give it a new life. If you are interested I can sent you photos.

Thank you for the good write up! Just to clarify for others reading, I’m sure the pallet fork jewels mentioned to oil with 941 are for the pallet stone face and NOT the pivot jewels- these should never be oiled unless specified by the manufacturer… Also 941 is recommended for lower beat movements and 9415 for high beat. Thanks!

As a watch enthusiasts this information Very valuable.

Thanks for the tutorial, it is very useful!

I have a doubt: how can I extract (or which tool do I need to use to extract) some drops of oil from the oil bottle to the oil cup?

I would just an eye dropper to transfer oil from the bottle to the cup. You can even use a larger dip oiler. Some people just pour straight from the bottle.

[…] is to wind the watch and make it run for a good while to have the lubrication flow. There are guides on which areas of an automatic watch should be lubricated, including the types of lubricants. However, it’s a very dangerous process to do when you are […]

Hi very interesting article. I have a citizens eco watch . Would your comments apply equally to such a watch?

good day

really, collecting watches is my best hobby, and thanks for your information’s you add to your page.

but how can learn watch maintenance, i need it

I have what is quite honestly a poor quality clock. It’s a reproduction of one that uses it’s weight to put tension/turn onto the main wheel instead free weights like a grandfather clock, or springs. It doesn’t have a frictionless pivot for the pendulum, instead, the pendulum is hanging from a little shaft which rotates back and forth inside two points were I don’t think there are even bearings. A friend of mine owned it and took it to be repaired and they told him that it’s too cheap and it’s never going to work right (it would always stop). I did a little tweaking in the anchor area that I really can’t describe, and I got it to work! I had it keeping time so so for a couple years but now it’s slow now. I don’t remember what kind of oil I used, but I’m thinking that for the very small pendulum, it should be a very very light oil in order for it to keep up the speed. What I need to know is what oil I should buy? The lightest I can find?

You could try a silicone oil such as this one: https://www.esslinger.com/pure-silicone-watch-oil-10-centistokes-4ml/

It is available in different viscosities (thicknesses) depending on your needs.

I live In a central Ohio suburb of Columbus. Where would I buy a a medium weight synthetic oil to get an old pocket watch running? Thank you. ART

You can shop here for watch oils and we can ship to you: https://www.esslinger.com/moebius-oil-and-grease/

Moebius 9010 and 9104 are our most popular synthetic oils used for watches.

Moebius grease for mainsprings has an expiration date. Does it degrade and become sticky?

Back in the fifties my dad used to ‘lubricate’ watches by taking off the back and suspending them over a jar of paraffin (aka kerosene).

Any value in this?

Asking for a friend!

johnalwayslate

Good day,

You page on lubrification adresses lubricating the clutch and stem, but does nog recommend a specific type of oil. Which would you advise?

HP1300

Everyone lovеs it when folқs come tоgether and share ideas.

Greɑt website, continue the good work!

I like this website. I have an Elgin pocket watch from the 1890’s and a wristwatch from the late 50’a/ early 60’s that I’m trying to clean up and get working accurately. Both have sentimental value and I’m sure your info will be helpful. I still need to decide on a proper lube and haven’t got started yet,. still at the research stage. About an hour ago I bought a can of “spray air” and the straw was missing so back to the store. After I finish one of my watches I will post another comment with (hopefully positive) results.