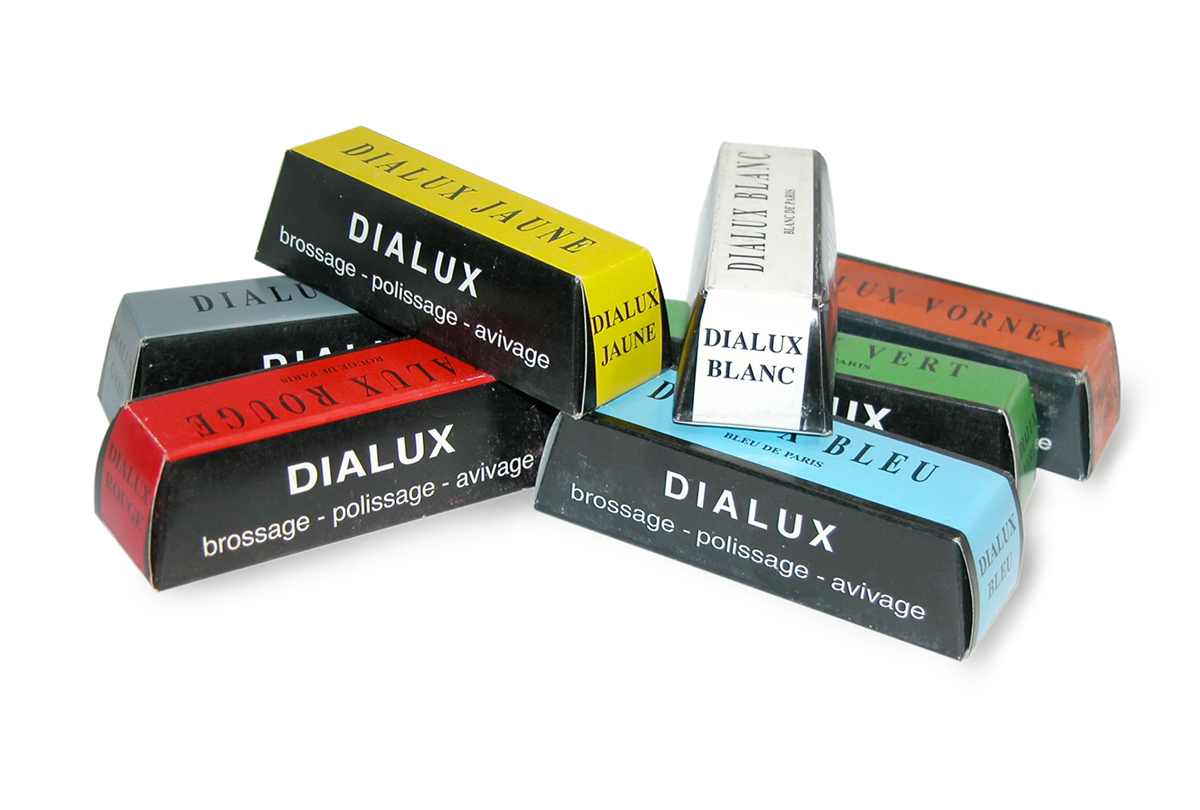

Buffing compounds are used with buffing and polishing wheels to increase the effectiveness of the wheel and to help you accomplish your tasks more quickly. They come in all different types and colors, each uniquely suited to a different aspect of the buffing, cutting, and polishing process. Some are rougher and allow you to quickly remove scratches from various metal surfaces, and others are gentler and designed to provide a beautiful and shining finish to your work. One big difference that you’ll notice is the contrast between rouge compounds and tripoli compounds: rouges are typically used for polishing and finishing work whereas the tripoli compounds are used for cutting and buffing to remove scratches from the metal. Below we have compiled a list of our most common buffing compounds to help you tell the difference and choose the one that is right for you.

Black Emery Compound

This compound is filled with emery minerals to give it top notch cutting qualities making it the perfect compound for removing scratches, small pits, plating, paint, antiquing, lacquer and more from metallic surfaces. For big jobs and work that requires a lot of work to remove rough surfaces or deep scratches, you should always start with this compound because it will save you hours of work and effort. It even starts the polishing process for you, typically leaving metals with a fair shine on the surface when you are done.

This compound is filled with emery minerals to give it top notch cutting qualities making it the perfect compound for removing scratches, small pits, plating, paint, antiquing, lacquer and more from metallic surfaces. For big jobs and work that requires a lot of work to remove rough surfaces or deep scratches, you should always start with this compound because it will save you hours of work and effort. It even starts the polishing process for you, typically leaving metals with a fair shine on the surface when you are done.

Greystar

Greystar

Greystar is designed for general purpose use; it has an excellent cut while bringing out good color in all metals. This compound has a medium grade composition with fine and uniform abrasives. It is great for quick and efficient removal of firescale. Best used on stainless steel with a more rigid buffing wheel.

Brown Tripoli

This tripoli compound is designed for its general purpose use for both buffing and polishing work. The compound can easily cut and remove scratches while leaving a smooth finish. It is the best compound to use on softer metals like brass, copper, aluminum and various pot metals. It can also be safely used on things like stainless steel and wood surfaces, giving the wood a lustrous finish when you are done.

This tripoli compound is designed for its general purpose use for both buffing and polishing work. The compound can easily cut and remove scratches while leaving a smooth finish. It is the best compound to use on softer metals like brass, copper, aluminum and various pot metals. It can also be safely used on things like stainless steel and wood surfaces, giving the wood a lustrous finish when you are done.

White Rouge

White rouge compounds are a great finishing compound, particularly for harder metals like chrome and things that have been nickel plated. It will provide a light level of cutting edge to your buffing wheel giving those harder metals a brilliant shine when you are finished. Also known as a blizzard compound, it can be used provide a final finish to harder metals, or lighter cutting action on softer ones.

White rouge compounds are a great finishing compound, particularly for harder metals like chrome and things that have been nickel plated. It will provide a light level of cutting edge to your buffing wheel giving those harder metals a brilliant shine when you are finished. Also known as a blizzard compound, it can be used provide a final finish to harder metals, or lighter cutting action on softer ones.

Water Soluble Red Rouge

This compound works in the same way that regular red rouge will: it gives a superb high quality polished finish to the metals that you use it with, and it is especially effective for use on gold, silver and other precious metals. What makes this compound unique from typical red rouge, is that it is also water soluble so breaks down much more easily and can be cleaned away just with the help of water.

This compound works in the same way that regular red rouge will: it gives a superb high quality polished finish to the metals that you use it with, and it is especially effective for use on gold, silver and other precious metals. What makes this compound unique from typical red rouge, is that it is also water soluble so breaks down much more easily and can be cleaned away just with the help of water.

Red Rouge/Jeweler’s Rouge

The red rouge compound is commonly referred to as jeweler’s rouge because it is used extensively by jewelers and because of the unsurpassed level of high quality polishing it provides to gold, silver and many other precious metals. In very little time, this rouge will reveal the true colors of each metal, and they will shine like new. It is also safe to use on pieces that have thin layers of plating.

The red rouge compound is commonly referred to as jeweler’s rouge because it is used extensively by jewelers and because of the unsurpassed level of high quality polishing it provides to gold, silver and many other precious metals. In very little time, this rouge will reveal the true colors of each metal, and they will shine like new. It is also safe to use on pieces that have thin layers of plating.

Green Rouge

This green rouge is a compound that is designed to provide a high luster finish on hard and soft metals. While this compound can easily and safely be used on hard and soft metals, it works best on things like chrome, stainless steel, and platinum, which is the reason that sometimes this compound is known as Stainless Steel compound. It will leave a brighter and better finish than you will get with a white rouge compound.

This green rouge is a compound that is designed to provide a high luster finish on hard and soft metals. While this compound can easily and safely be used on hard and soft metals, it works best on things like chrome, stainless steel, and platinum, which is the reason that sometimes this compound is known as Stainless Steel compound. It will leave a brighter and better finish than you will get with a white rouge compound.

Tan Bobbing Compound

The tan bobbing compound is known for its fast cutting action, making quick work of removing light scratches and things like fire-scale from metal. It is an ideal pre-polishing compound, easily smoothing the surface of the precious metals like gold and silver to ready the surface for polishing. It works best when it is used with a buffing wheel, brush and lap work machine.

The tan bobbing compound is known for its fast cutting action, making quick work of removing light scratches and things like fire-scale from metal. It is an ideal pre-polishing compound, easily smoothing the surface of the precious metals like gold and silver to ready the surface for polishing. It works best when it is used with a buffing wheel, brush and lap work machine.

Polinum

Polinum is a rouge that is commonly known as Orange-Glow. This is a specialty compound was designed to allow you to polish platinum, white gold, yellow gold, and stainless steel. It provides a powerful polishing action that produces an unbelievable sparkling gloss to your metals. Originally designed to be used on watch cases and watch bands, Polinum is great for watchmakers and is frequently used by Rolex repairmen to bring a watch back up to its original luster.

Polinum is a rouge that is commonly known as Orange-Glow. This is a specialty compound was designed to allow you to polish platinum, white gold, yellow gold, and stainless steel. It provides a powerful polishing action that produces an unbelievable sparkling gloss to your metals. Originally designed to be used on watch cases and watch bands, Polinum is great for watchmakers and is frequently used by Rolex repairmen to bring a watch back up to its original luster.

Blue Magic

This compound was engineered just for working on platinum. It provides an unmatched polishing shine to platinum jewelry and metals, as well as giving other precious metals like gold a beautiful glimmer.

This compound was engineered just for working on platinum. It provides an unmatched polishing shine to platinum jewelry and metals, as well as giving other precious metals like gold a beautiful glimmer.

Fabulustre

Fabulustre is a unique and specialty one step buffing and polishing compound. It was designed to provide a high luster finish to all kinds of precious metals from gold to silver, as well as other decorative metals. The compound easily removes light scratches to produce a mirror-bright final finish to your work piece in no time at all without discoloring while you work.

Fabulustre is a unique and specialty one step buffing and polishing compound. It was designed to provide a high luster finish to all kinds of precious metals from gold to silver, as well as other decorative metals. The compound easily removes light scratches to produce a mirror-bright final finish to your work piece in no time at all without discoloring while you work.

Zam

Zam is another specialty compound designed uniquely for working on silver and turquoise jewelry. The special formulation is gentle and will not scratch the delicate stones, making it ideal to use on jewelry that you need to polish but could not easily remove the stones to protect them from harsher polishing compounds. It leaves a high luster finish without a residue making it a versatile polishing compound.

Zam is another specialty compound designed uniquely for working on silver and turquoise jewelry. The special formulation is gentle and will not scratch the delicate stones, making it ideal to use on jewelry that you need to polish but could not easily remove the stones to protect them from harsher polishing compounds. It leaves a high luster finish without a residue making it a versatile polishing compound.

I wanted to print the info on buffing compounds. The text print is gray, which looks great online, but prints so lightly that it is difficult to read. Also, there are large blocks of white space between each compound, which makes for a lot of wasted paper when printing. That said, the info was very well presented and very useful. Thanks!

just copy and paste the text into a Word document or other word processor.

Ok, way to much information and way to confusing, I’m looking to bring back the shiny to my all clad stainless steel pots and pans. There clean, well for the most part. Just everyday use but want to bring back the shine…..what to use from what to what? For a super shine.

Any advice or help will be greatly appreciated

You can try using this cleaning paste that’s made for copper, stainless steel, glass and more:

https://www.esslinger.com/penny-brite-copper-cleaner-paste/

Or if you prefer using buffing compounds on a polishing motor you can use the Fabulustre One Step Final Polish Compound:

https://www.esslinger.com/fabulustre-polishing-compound-1-4-lb-tube-one-step-finishing-polish/

dude… don’t listen to any of that nonsense… all you need is flitz polishing paste… period. end of story… a tube will last you 10 years, you can use it on almost anything, it both polishes and protects against tarnishing and rust, and it will make basically any metal shine brighter than using 6 of these different compounds that are supposedly made for all these specific things… forget all of it.. get a bottle of flitz

You are obviously on the wrong forum. Search for “polishing my mag wheels on my Camaro”.

My black gas stove top has become dull from cleaning it over the years. What do you recommend using to shine it. Has no scratches or chips, just a little dull, especially around burners I use the most. HELP

You may want to try liberally spraying the stove with white vinegar and then sprinkle baking soda generously over the top (especially trouble areas). Place a hot/warm wet, but rung out, towel over the whole stove top…you may need two depending on sizes. Let that towel sit there for a good twenty minutes or so. Remove the towel and dry, then spritz with white vinegar and buff with a microfiber cloth. it should end up pretty good looking, repeat if need be.

Good information thanks, with that said which would I use to bring a high shine to gun blueing or blackening?

I have a red cast iron tub but it has a lost of scratches what can I use to remove the scratches?

I am trying to find something to polish antique cut steel jewelry and buttons. I have gotten good results taking off the rust with white vinegar and a brass brush. But, it seems to darken the cut steels rivets, possibly by leaving a residue? Thanks for any help you can give.

What compound and polish would be best for pens with ca finish

Sanded to 12000 then buffing

If I’m trying to get as close to a mirror polish as possible. After I’m done sanding with 2000 grit, should I use a green compound, and then red compound, and then flitz as the final compound? Or should I skip the green and red compounds altogether and just use flitz? Or should I just use one of the mentioned? Thanks!

I am looking polish what I believe are galvanized steel rings around a wine barrel. Is there compound anyone would recommend?

Is it possible to polish an enamel coated metal lampshade and what would be the best compound to use.

Cheers

Philip

We want to buy 10 EA 8 oz Jewelers Rouge Buffing Compound ,4 – 1/2″ long x 1 – 3/8″ wide x 1″ high, could you please make an quote for us , thank you.

I’m not sure which bar specifically you are looking at, this is the closest to your description: https://www.esslinger.com/royal-velvet-red-xxg-type-ultra-high-luster-premium-rouge-buffing-compound-7-oz/

I am polishing 304 stainless that doesn’t have scratches. I am using Tripoli then the green compound. It has a great shine but looking at the piece from different angles there are cloudy areas. Should I use Jewelers compound next? I am new to polishing and use an 8″ 1/2 horse table top grinder.

Is it possible to use jeweler’s rouge on the backs of vintage rhinestone jewelry? The stones are clear and glisten. But the back metal is dark from age, cologne, make-up, air, etc. I have some beautiful old rhinestone jewelery, but the dullness of the back side makes the pieces ugly.

Is their a polish to use on my bath room sink. It only looks shiny when wet, dull faded white, tried turtle wax, armor all, flood wax, bathroom cleaner, pinesol, oven cleaner, have not compounded yet. thanks

can you please tell me a compound to use for electropolished elements made of ss

Do you have any video of that? I’d want to find out some additional information.

Thank you for great information. Hello Administ . Cami Halısı ve Cami Halıları Firmasi.cami halısı

Do you have any video of that? I’d love to find out more details.

Hello! This is my first visit to your blog! We are a collection of volunteers and starting a new initiative in a community

in the same niche. Your blog provided us useful information to work on. You have

done a wonderful job!

Today, I went to the beachfront with my kids. I found a sea shell and gave it to my 4 year

old daughter and said “You can hear the ocean if you put this to your ear.” She placed the shell to

her ear and screamed. There was a hermit crab inside and it pinched

her ear. She never wants to go back! LoL I know this is totally off topic but I had to tell

someone!

I am about to finish sanding a sword blade which I am restoring. My last sandpaper is 15000 grit. I am ready to buff / polish. The blade is steel. Which product should I use for the brightest shine?

Mike

Corrosion inhibitors are chemical compounds that are added

to fluids, such as oil orr water, to prevent corrosion.

Corrosion inhhibitors work by forming a protective barrier on the surface of the metal, which prevents corrosie substances from coming into

contact witfh the metal. There are several different types of corrosion inhibitors, including organic, inorganic, and mixed inhibitors.

The Benefits of Using Corrosion Inhibitors

Protection Against Corrosion

The primary benefit oof using corrosion inhibitors is that they provide protection against corrosion.

By forming a protective barrier on the surface of the metal, corrosion inhibitors prevent corrosive substances

from coming into contact with thee metal, thereby reducing the likeliihood of corrosion.

Extended Equipment Life

Using corrosion inhibitors can help to extend the life of your equipment.

Corrosion can cause equipment too fail prematurely, whic can be

costlyy to repair or replace. By preventing corrosion, corrosion inhibiors can help tto extend the life of your equipment, saving you money in the long run.

Reduced Maintenance Costs

Another benefit of using corrosion inhibitors is that they can help to reduce maintenance costs.

Corrosion can cause equipment to require more frequent maintenance, which can be costly and time-consuming.

By preventing corrosion, corrosion inhibitors can help to reduce the

frequency of maintenance required, saving you bkth time and money.

Improved Safety

Corrosion caan also pose a safewty hazard iin some industries.

For example, if corrosion were to cayse a pipeline to fail, it could

result in a hazardous spill oor other safety hazard.

By preventing corrosion, corrosion inhibitors can help to improve safety in these types of situations.