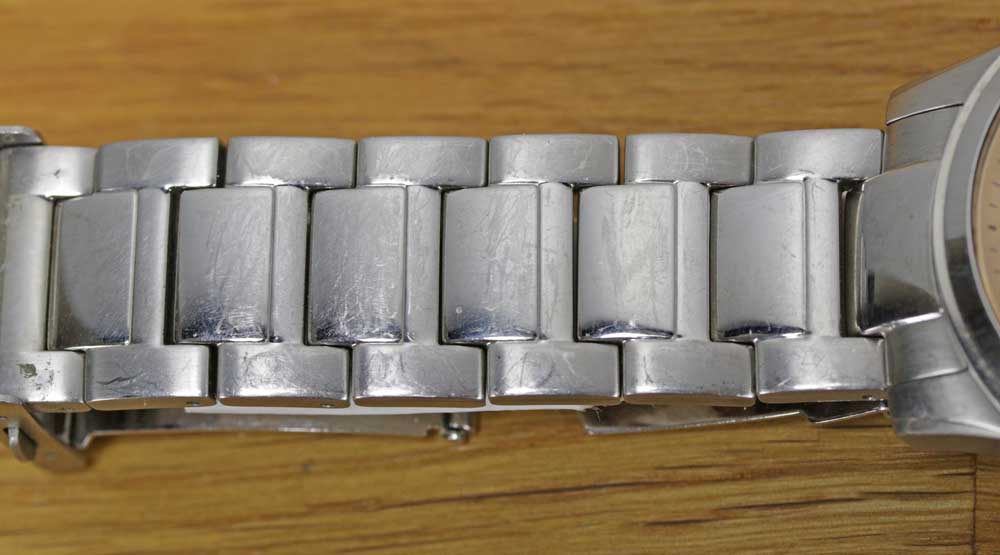

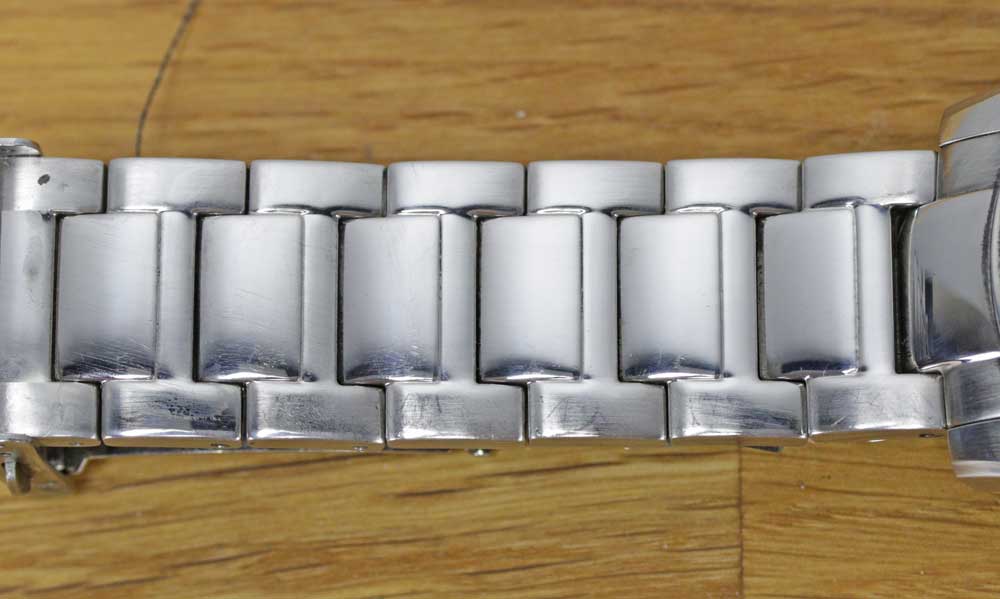

Your stainless watch is looking worn and scratched? It can look like new again with just a few of the right tools and a short time. Smooth out deeper scratches and remove light scratches almost entirely. The process of polishing stainless steel starts by using an abrasive compound to work on getting the deeper scratches out before working your way to a final polish to achieve a bright polished finish. When polishing it is important to not over polish your watch case/bezel/band because you are actually removing metal and could remove too much. This method will teach you how to polish a watch without taking the watch apart or removing any parts.

Items Needed:

- Stainless Steel Polishing Kit # 99.212

- Two 4″ muslin buffs

- Two 4″ satin buffs

- Greystar abrasive compound

- Fabulustre final polishing compound

- Polyimide tape

- Rouge embedded polishing cloth

- Polishing Motor

- Finger Cots

- Cleaning Solution / Ultrasonic Cleaning Machine

Bright/Mirror Polish

Step 1

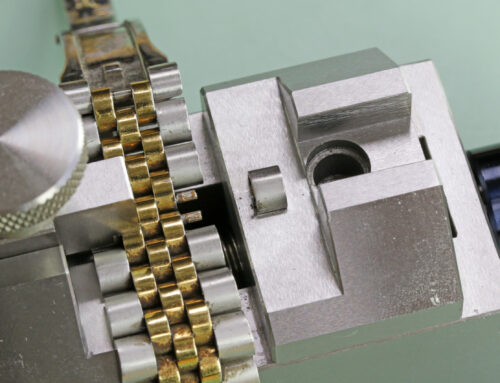

A.) Begin with getting your polishing motor ready; place your muslin buffs on the spindles with the motor running.

Note: If the watch band is really dirty, it helps to clean it up before polishing either scrubbing between link or remove the band and use an ultrasonic machine. The dirt in the band can spread and “melt” as you polish leaving you with more of a mess.

C.) Apply your grey star compound to the buff, with a gentle touch apply a small amount to begin with – you don’t want excess compound on your buff. You can always add more when needed during the polishing process.

Note: Always use safety goggles and gloves or finger cots at the least when buffing. Use a dust collector hood behind each buff to prevent debris flying around. For more safety information, click here.

Step 2

We will be polishing over both the bright and brushed finish on the watch without using protective tape. This step focuses on the deep scratches and the bright polished areas as the brushed area will have a matte finish put back on in the end.

With medium pressure, start pressing your watch into the buff. Keep the buffing wheel moving in the same direction down the watch band to keep the polish uniform. To prevent excessive wear or distortion, keep the watch moving all the time and never polish holding in one place for long periods of time. It is unusual to find a completely flat area of any watch so if you do have a surface that is flat and sharp on the edges, you would polish those using a hard felt wheel.

For watch case backs, you can lightly polish them with a rouge cloth but you won’t be able to get the deeper scratches out without removing about 1/8″ or more of the metal and removing the engraved material. The only real way to get rid of deep scratches is to laser weld to fill them and this repair is very costly.

Polishing the watch bezel

You can leave the crystal in the watch if you use a light touch when polishing the bezel. To make sure the crystal won’t be scratched it might be best to remove the crystal before polishing. How to remove a watch crystal.

Another option is to just polish the bezel with a rouge cloth.

Polishing the case

You want to avoid polishing directly on the crown and chronograph buttons to prevent removing the logo, pattern, or knurled grip. There is also a chance they could break off from the pressure. You can use a flex shaft machine to polish the case in and around them – we suggest using 3M® Radial Discs. For higher end watches, you should disassemble the watch removing the movement, all gaskets, glass, and buttons, and detach the watch strap.

Step 3

After each step of polishing we advise that you clean the watch to remove the compound residue. If you don’t clean it off it will contaminate your next polishing wheel and make it more abrasive than intended. You end up with a wheel that has both your polishing compound for a mirror finish and your abrasive cutting compound, and the final polish won’t be as effective.

Use a cleaning solution with a brush to scrub the band between the links and around the case. Dry with a lint free cloth before moving to the next step.

Step 4

Repeat step 1 and 2 with the Fabulustre polishing compound on a new buffing wheel to get a final bright polish for your watch.

Step 5

After you’re done with the Fabulustre compound the watch will be really dirty with a build-up of compounds, especially between the links. Scrub with the cleaning solution really well and dry with a lint free cloth before moving to the matte finish accents.

Brushed/Satin Finish

Step 1

A.) Now that our bright areas are polished to a mirror finish, we will put the matte/brushed finish back on to the other areas. Start by using the polyimide tape to protect the bright polished areas you just did from getting a brushed finish. You don’t want to re-polish what you just polished because it accidentally got a brushed finish treatment.

C.) When using the satin wheels, its best to start with a fine grit and move your way to a coarser grit until you reach the desired finish.

With medium pressure, start pressing your watch into the wheel. Keep the satin wheel moving in the same direction down the watch band to keep the lined brush strokes uniform. If you prefer the unlined (sand-blasted) brushed finish you can use the wheel in several directions for a matte finish.

Polishing the case

You want to avoid polishing directly on the crown and chronograph buttons so they don’t break. You can tape over the buttons to protect the finish or you can use a flex shaft machine to polish the case in and around them – we suggest using 3M® Radial Discs. For higher-end watches, you should remove the buttons and crown before polishing.

Step 3

Take the tape off and clean the watch. For a great result take the watch band off the watch and clean it in an ultrasonic cleaner and then steam pressure spray out for a final cleaning.

Results

Some Precautions

There are several watches that can be polished without taking them apart but if you decide to polish a watch without taking it apart there are some risks:

- Gaskets can fail and leak dirt and moisture

- Components can be broken or scratched

- Buttons, clasps, and crowns can catch on the buff and get damaged

- If you drop the watch while polishing, the watch can be broken or damaged

DISCLAIMER: While the repair you are about to attempt may seem simple, the slightest mistake can result in you damaging or ruining your watch. If you have any doubts about this repair, do not hesitate to take your watch to a professional watchmaker or jeweler.

Thanks for sharing information in detailed view.

Thank you very much for the detailed information in regard to appropriate rouge (or Tripoli.) to use.. I intend to use a Dremel tool, cautiously, on my high-value Timex watches!

Presuming that the results will be excellent, I will move up to my Armitron watches.!

Eventually I suspect I will work my way all the way up to my Patek Philippe watch! Polished or not, I fear that it will always remain the fake that it is.

C’est la vie…

What grit is used for brushing the watch? Is it 3000 grit?

When buffing and polishing a mirror finish watch bracelet, how do I avoid or remove the fine scratches that the buffing leaves? It seems to look like a brush finish.

You start with a red rouge polish or whichever polish you need to remove scratches and then work your way towards creating the final polish with Fabulustre or other high polish compounds. Make sure you are using different buffs for each compound, otherwise the “grittier” polish will leave scratches behind while you’re trying to do your final polish.

The link to purchase the polishing kit is dead