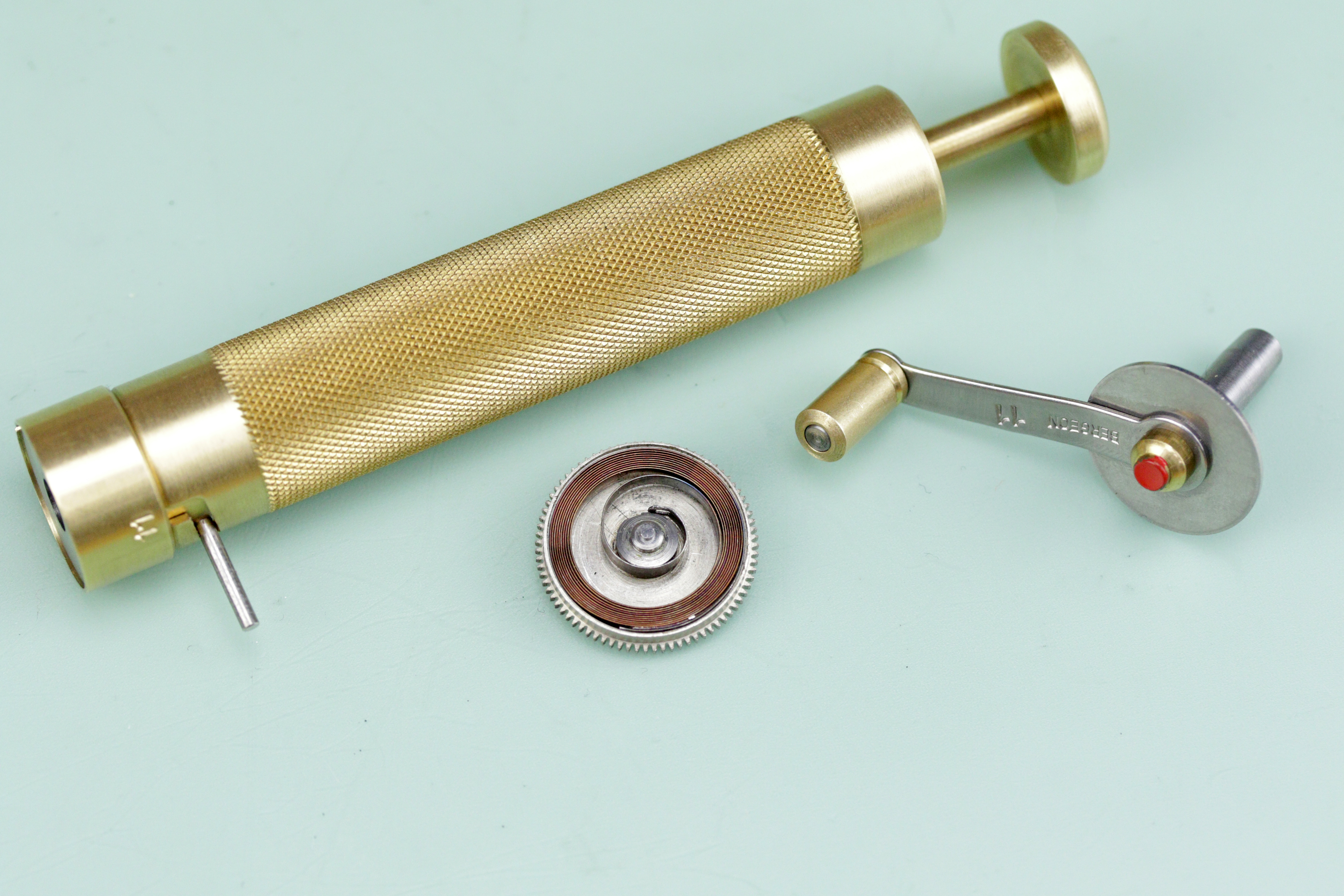

Winding a mainspring and getting it back into the barrel can be a challenge if you don’t have the right tools at hand. Bergeon makes a complete set of mainspring winders for just about any watch and they are pretty easy to use. For anyone that isn’t sure just how to go about getting a new or re-greased mainspring back into the barrel, here you will find the how-to.

Before you begin winding your mainspring you first need to tell if it needs to be wound clockwise or counter-clockwise. Most mainsprings are wound clockwise (spirals from the center to the right) – you can see this when you open the barrel and look down into the mainspring while it’s still in the barrel. There are some mainsprings that are wound counter-clockwise and this is why Bergeon makes “right” and “left” handed winding arbors. They are specified by a red (right-hand) or blue (left-hand) dot.

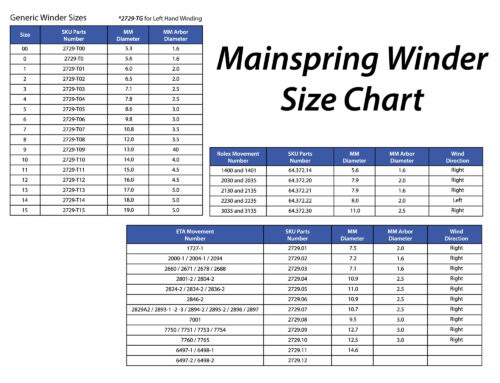

To find the right size winding drum and arbor, simply find one that is the closest fit (without being larger than) to the inside of the barrel.

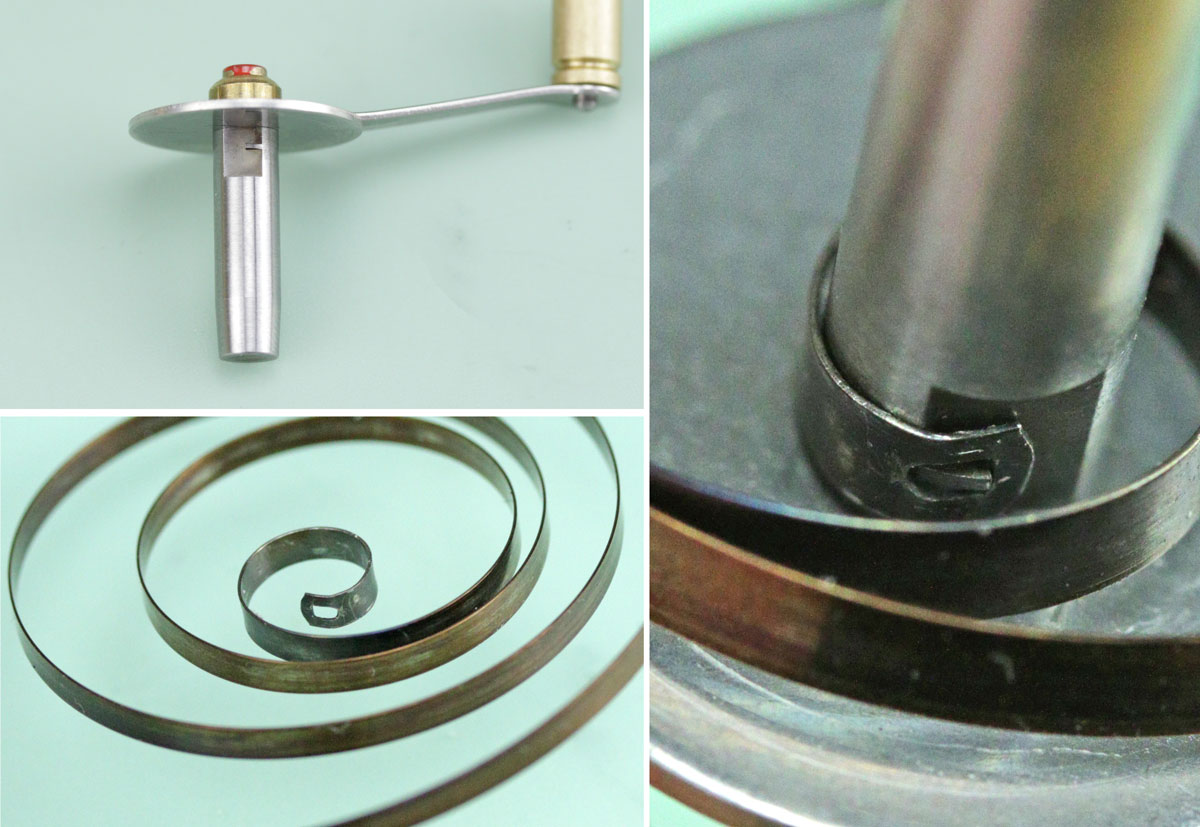

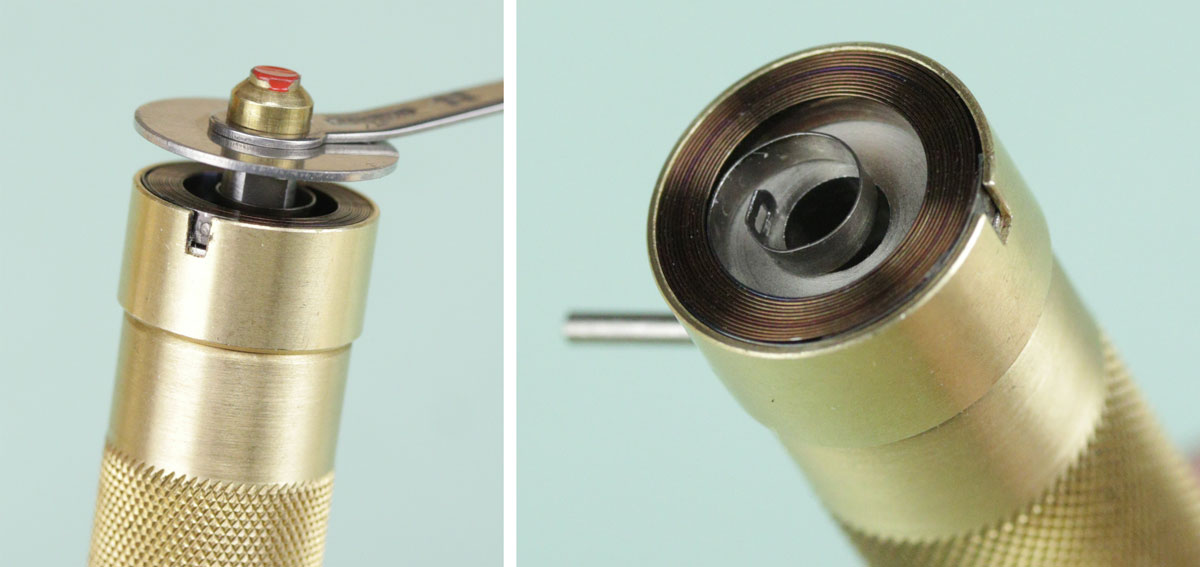

Install the winding drum into the mainspring winding handle and lock into place. Slide the peg on the drum into the slot on the handle. Then you will need to get the end of the mainspring started onto the arbor. The beginning of the mainspring will have a hole that fits onto the hook that is found on the winding arbor.

Installing the mainspring onto the arbor is done in the opposite direction as it is wound, because most mainspring winders stage the spring as if you are looking at the mainspring from the floor side of the barrel instead of the top, looking down. Therefore the mainspring will spiral counter clockwise into the winder and the mainspring winder will turn clockwise to wind the spring into the tool.

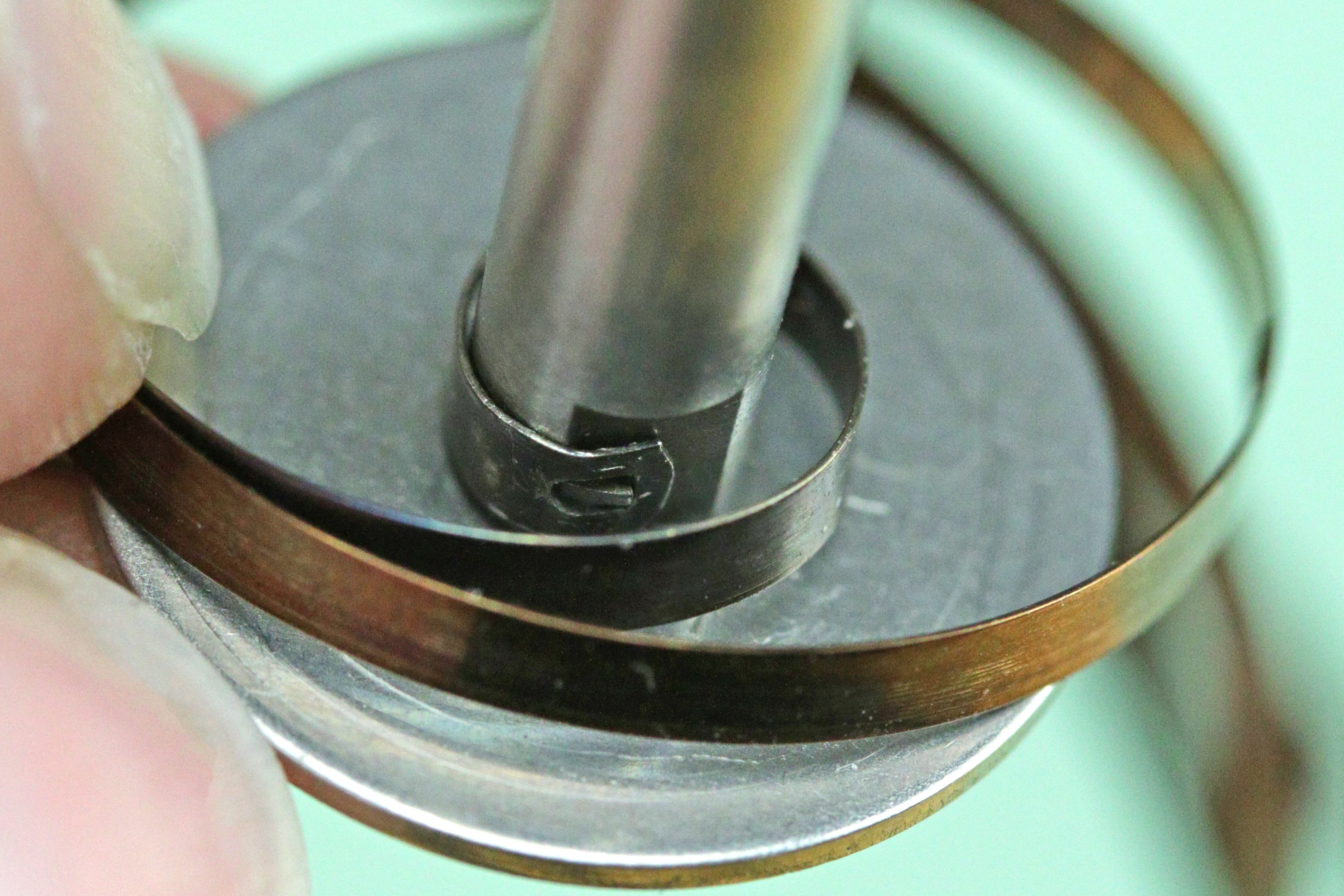

Install the arbor with the mainspring “mounted” into the drum, making sure that the spring feeds through the notch on the side of the drum once the arbor is all the way in place. Begin turning the handle of the arbor clockwise to wind the mainspring into the drum.

Continue winding the mainspring until the whole length is wound inside the drum. It is a good idea to wind it back a couple of rotations until the tension is released from the handle.

Carefully remove the arbor out of the drum; the mainspring might still be caught on the hook and could pull be pulled out of the winder. Then you need to place the drum down into the open barrel and press the plunger down on the handle to lower the wound mainspring into the barrel. You will hear a click or feel it release into the barrel. Now you have a fully wound mainspring installed in the barrel!

I think you have a slight error in the paragraph starting installing the mainspring into the arbour

It says Therefore the mainspring will spiral counter clockwise into the winder

This should read

Therefore the mainspring will spiral counter clockwise into the barrel

These two look left handed:

https://blog.esslinger.com/wp-content/uploads/2019/12/starting-mainspring-on-the-winder-tooth.jpg

https://blog.esslinger.com/wp-content/uploads/2019/12/starting-mainspring-on-the-winder-tooth.jpg 1200w

Actually, no, they go on the winder the way they will end up in the barrel

Sort of a double negative…

I confer with James Berry. It looks left handed at first until you realise you are looking at it upside down.

During lockdown I started playing with thie insides of my watch. I do batteries and small repairs in addition to being a jeweler. I’m wondering where I could get information on measuring for a new stem and crown? Any help would be great. Thanks!

Here are some helpful articles for you:

How to replace a stem: https://blog.esslinger.com/how-to-replace-a-watch-stem/

How to Replace a crown: https://blog.esslinger.com/how-to-replace-a-watch-crown/

How to measure a DP crown without the crown: https://blog.esslinger.com/how-to-measure-a-dustproof-quartz-watch-crown-without-the-crown/

How to measure a WP crown without the crown: https://blog.esslinger.com/how-to-measure-a-waterproof-quartz-watch-crown-without-the-crown/

These articles also have links to other articles that may be helpful or just use the search bar if you want to find more information.

How do I find out what the actual outer diameter of Bergeon’s watch winders is. I’m currently working with some Valjoux 7733/7734 and movements and related Poljot 3133 movments. The inner barrel diameter of the 7733 and that of the 3133 is about 12.4 mm. What Bergeon mainspring winder should I choose for these movements.?

If the inside barrel measurement is 12.4mm, then I would choose the 12mm winder since it is the closest we have and will fit inside the barrel. You can shop for winders here: https://www.esslinger.com/bergeon-mainspring-winder-1/

Your website is fantastic! I collect watches but always wanted to be able to repair them. Thanks to you, l am pretty sure l will be starting a new hobby.

I don’t see the need to make separate left and right hand winder handles, they could easily make it “ambidextrous” with a two-way entrance. That would mean the only extra tool to buy for opposite handedness is the winding arbor.