Quite some time back I became the owner of a Patek Philippe, open-face Pocket watch movement vintage 1885. I suspect that it fell victim to a rise in Gold prices prior to the 1990s. At any rate the movement had lost its “home”. Given that fact that a Patek Philippe is regarded as a prestigious watch it deserved to have a new “Habitat” (hence the play on words “Habitat For a Horologe).

The problem was that the size of the movement did not match any American Size watch cases. However a size 16 case could be adapted if an adapter ring could be made that would have the inside diameter the same diameter as the outside of the movement and the outside diameter would have to match the inside diameter of the case. In addition both the shape of the movement edge as well as the contour of the inside of the case had to be accommodated.

I had in my collection of watch cases a nice Gold Filled case with hinged back covers (both dust and outside) as well as a hinged bezel.

The winding stem for the Patek was both wind and set utilizing a detent to hold the stem in place in the watch movement. That meant that the sleeve in the existing case would have to be removed and the stem would have to be adapted to fit the sleeve diameter in the case. That was the easy part. Now came the task of making the reducing ring. Given that the finished thickness of the ring would be less than 3 mm. and be nearly a ¼ inch in width. I had a scrap of brass that was ¼ inch thick. At the suggestion of a machinist friend of mine I used a good grade hole saw that produced a disk with an outside diameter just slightly larger than requiredcase diameter.

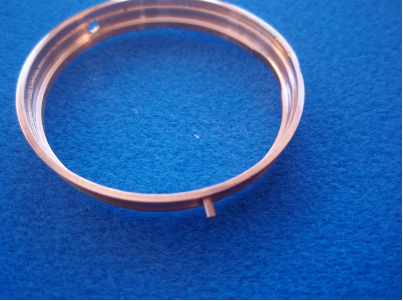

Using a three jaw chuck on my unimat lathe I began to fashion the diameters that would fit the outside of the movement. Because the width of the finished ring would be less than ¼ inch I left the remaining thickness in order to provide the necessary strength to the disk while the outside diameter was reduced to fit the case diameters. Then by reversing the disk and using a watch lathe bezel chuck (which has 6 jaws) I was able to finish the outside diameter of the adapter ring. But before removing the surplus thickness I needed to fashion the recesses for the movement case screws. The next step was to drill the hole in the ring to accommodate the winding stem as well as a hole that would be set at an angle and have a pin inserted to secure it to the watch case. All of this could be done with the remaining thickness providing the strength so that the ring would retain its shape. I also had to mill a recess into the inside of the ring to provide clearance for the balance wheel. Now the ring could be reduced to the proper width and the remaining thickness removed to form the finished adapter ring.

Now I have a watch that I can carry if I choose and with the hinged back I can prove to my fellow watch collectors that it really is a Patek. The plain dial while it is anoriginal Patek dial does give evidence that it is a Patek. But now I have waiting in the wings a couple Vacheron & Constantin as well as an A. Lange & Sohne movement all seeking new “homes”.

Written By

- Elmer Westerman

Leave A Comment