Sometimes your watch band clasp will wear out before your watch band does. If you don’t want to replace your whole watch band you can always just replace the clasp itself. Use this guide to learn how to change tri-fold style watch band clasps with a security catch.

Sometimes your watch band clasp will wear out before your watch band does. If you don’t want to replace your whole watch band you can always just replace the clasp itself. Use this guide to learn how to change tri-fold style watch band clasps with a security catch.

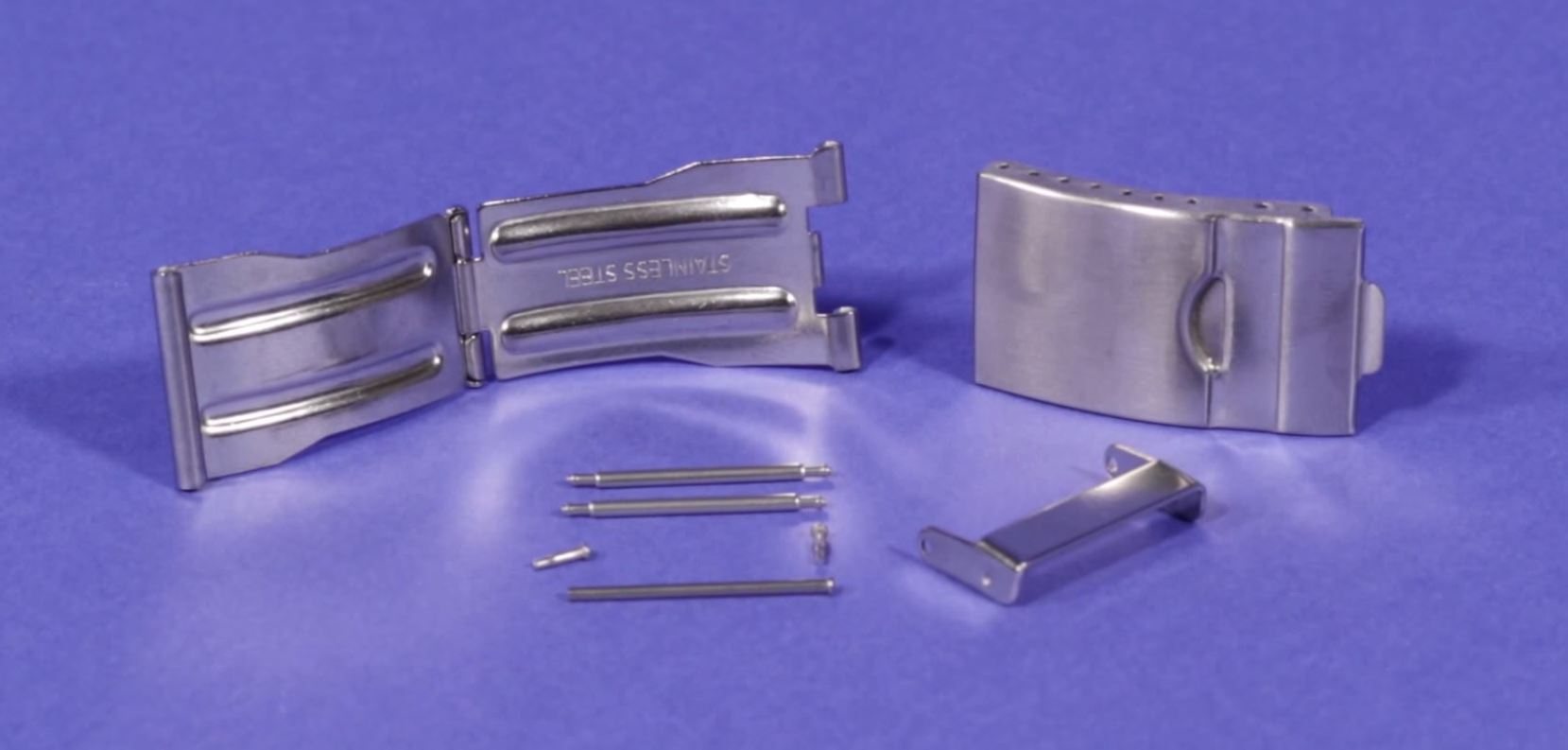

How will you recognize a tri-fold clasp with a security catch? When the clasp is open three metal plates and two joints, when it is closed the two lower plates will fold under the out clasp that matches the watch band style. If it has a security catch, it will have a metal tongue that locks over the top of the clasp when it is closed.

Tools Needed:

Tools Needed:

- A flex shaft and cutting disc

- A pair of protective glasses

- A pin punch

- A jeweler’s ball peen hammer

- A watch band holder

- A digital gauge

- A parts tray

- An extra friction pin

- An extra spring bar

- A replacement tri-fold clasp with security catch

Step 1

The first thing to do will be to remove the old clasp so you can replace it and continue wearing your watch. Start by opening the watch band to remove the security catch attached first. Hold the watch band on its side so you can see where the security catch attaches, it should have to ‘pin end covers’ hiding the friction tube from you.

The first thing to do will be to remove the old clasp so you can replace it and continue wearing your watch. Start by opening the watch band to remove the security catch attached first. Hold the watch band on its side so you can see where the security catch attaches, it should have to ‘pin end covers’ hiding the friction tube from you.

To remove this style pin, you will need your flex shaft with thin cutting disc or another tool that will allow you to cut the end cap from the friction tube. You will also want to put on a pair of protective glasses to protect your eyes from any flying bits of metal.

Take your flex shaft and hold the cutting disc perpendicular to the watch clasp with the edge of the blade close to the end cover. Hold the watch clasp securely and keep your fingers away from the edge where you are going to cut the cap off. Start the flex shaft and move the blade under the end cover to cut the tube and cover apart. When the cover falls loose, turn off your flex shaft and turn the watch over so you can cut the cover from the other end of the friction tube with your flex shaft like you just did. Once the second cover falls free, remove the security catch and set it aside.

Step 2

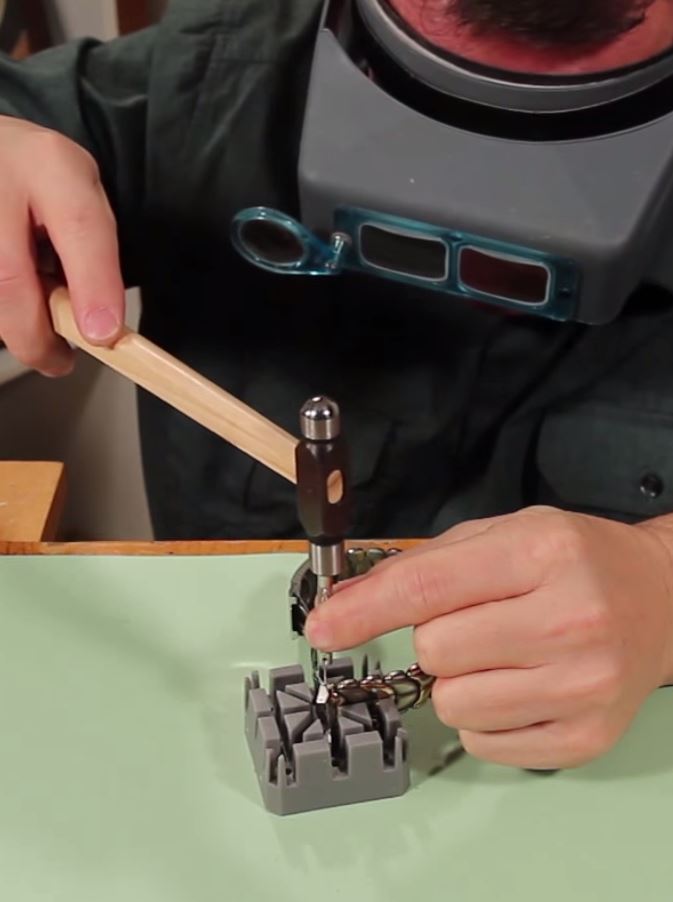

Next you’ll need to remove the tube inside this end of the watch band that is still holding the clasp to the watch band. Open the watch band clasp and insert it into your watch band holder so that the hole bottom layer of the clasp is aligned with a hole in the holder. Take your pin punches and find the one that fits snugly inside the hole and rests on the edge of the tube inside. Once you have the pin punch that fits your watch band, position the punch over the friction tube and gently tap on the punch with your ball peen hammer to remove the pin.

Next you’ll need to remove the tube inside this end of the watch band that is still holding the clasp to the watch band. Open the watch band clasp and insert it into your watch band holder so that the hole bottom layer of the clasp is aligned with a hole in the holder. Take your pin punches and find the one that fits snugly inside the hole and rests on the edge of the tube inside. Once you have the pin punch that fits your watch band, position the punch over the friction tube and gently tap on the punch with your ball peen hammer to remove the pin.

Gradually increase the pressure you apply with the hammer until the pin punch is steadily pushing the tube out of band. When you can’t push the pin punch any further into the watch band, set the punch and your hammer aside and remove the watch band from the holder. If the tube does not fall out of the watch band, grab it with your fingers and pull it out then set it aside in your parts tray.

Step 3

Let the first end of the old clasp and the security catch fall free of the watch band. It should be the ‘forked’ end of the clasp with a gap between the two tube ends of the clasp like this. Use the security catch here to help you remember which side of the watch band the forked end attached to so you can be sure that you place the new clasp correctly later.

Step 4

Then, position the watch band on your work surface so that the second end of the watch band clasp is in front of you, with the back of the watch band facing you. You should be able to see where the clasp overlaps the watch band and the tips of the spring bar that keep the band and clasp together at the outside of the watch band here.

Take your spring bar tool and, using the pointed end, insert the end into the hole in the watch band clasp where you noticed the spring bar. Push down on the spring bar to compress it, and then angle your spring bar tool to slide the watch band and compressed spring bar out from under the clasp. As the spring bar emerges from under the watch clasp, it may spring open again and fly across the room if you are not careful. Be sure to work carefully so you can keep the spring bar from escaping and place it in your parts tray to use later. Let the watch band fall apart and set the old clasp aside.

Step 5

Step 5

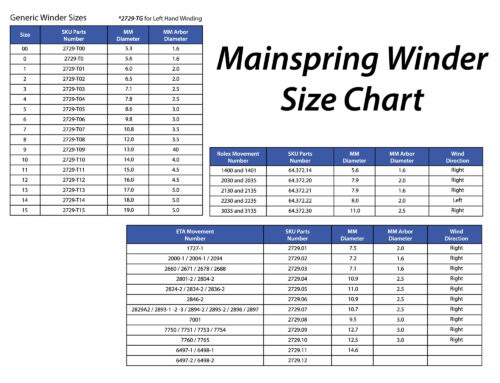

Next, use the old clasp to measure for the dimensions of the new clasp. Start by measuring the outside of the forked end of the clasp with your digital gauge. With that measurement in hand, you’ll measure the inside of the cover part of the clasp that fits over the watch band.

Use the backward opening jaws of the gauge to find this measurement. It should be about one millimeter larger than you first measurement. Order the right size and color replacement watch band clasp.

Step 6

When you have the new clasp in hand, you will want to start by attaching the cover end of the clasp to the watch band first. Take your spring bar and insert it back into the end that you removed it from earlier. Holding the watch band and the spring bar together, slip the watch band inside the watch clasp so that the outside of the watch band faces the inside of the watch clasp cover.

Align the end of the spring bar with the hole in the bottom of the clasp. Take your spring bar tool now and use the forked end to press the spring bar down into the watch band so you can slide it completely into the watch clasp end. Carefully remove your spring bar tool and wiggle the watch band around under the clasp until the spring bar slips into place in the hole in the clasp and expands again.

Step 7

Step 7

With the watch clasp partially attached to the watch band, you can now attach the other end of the clasp to the band. Take the two loose ends and hold them together so the forked end hugs the loose end of the band like this. Start to insert your friction tube into the clasp and band to hold them together and then place both parts into your watch band holder to keep them steady while you replace the friction pin.

Make sure that the pin hole is not lined up with a hole in the holder so you don’t accidently push it out of the band again. Tap gently on the end of the pin with your ball peen hammer to start to replace it in your watch band. As the pin slides further into the band, be sure to take your pin punch and put it between the pin and hammer to push it the rest of the way into place so you don’t hammer on the watch band itself and damage it.

Step 8

Step 8

When the pin is flush with the watch band again, you can remove the watch band from the holder and align the security catch with the holes on either end of the band and the friction tube. Hold these pieces together and replace the watch band in the holder. Then, grab your pin cover with your tweezers and insert it into the top hole in the security catch. Use your hammer to gently tap the cover into place until it is flush with the security catch.

Remove the watch band from the holder and flip it over to place the second pin cover in the other side of the security catch. Just like before, place the second pin cover with your tweezers and gently tap it flush to the security catch with your ball peen hammer.

Finished

Once the security catch is completely attached you can remove the watch band from the holder and wear it again with pride. To learn more about watch band repair, check out the rest of our Learning Center.

Leave A Comment